We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Editor’s note – This post and video originally appeared in The Wood Whisperer Guild, an innovative and high-quality website with tons of woodworking information. Many thanks to Marc Spagnuolo for making this paid content available for free on the Popular Woodworking site!

Buy Marc’s book, “Hybrid Woodworking,” in our store for an exclusive video with even more of this unique perspective on tooling for your shop.

–PWE

The Only Handplane You Need?

by Marc Spagnuolo

When I first ventured into the world of hand tools, I assumed I would eventually need every bench plane available. Chris Schwarz taught me that all I really needed were planes that satisfied the three basic classifications of coarse, medium and fine. Over time, I came to realize that a well-tuned low-angle jack plane might actually be the only bench plane I need, given the fact that my work does involve a hefty dose of power tools. So if you’re a new woodworker just entering the craft or perhaps you’re a power tool woodworker just dipping your toes into the hand tool world, a low-angle jack plane just might be the only plane you need.

The Low-angle Jack Plane

The plane I’m using for demonstration is the Lie-Nielsen low-angle jack plane. It’s modeled after the Stanley #62 and features a 14″ body and a bevel-up design. It currently retails for $245.

The Promise

The jack plane, as the name implies, is a “jack of all trades.” That means it should be able to tackle most of the coarse, medium and fine planing tasks we’ll require of it in the wood shop.

As with any “all-in-one” solution, there will be compromises. Because the plane body is somewhere between a smoother and a jointer, it may not be as perfectly suited for those tasks as the specific individual tools might be. Perhaps the 14″ body is too long to smooth a surface with minor hills and valleys. Maybe it’s too short to easily joint an extremely long edge. So if you are looking to be an exclusive hand-tool user, you may not be able to get away with using this plane as your only bench plane. But in my work, the low-angle jack is more than capable of handling just about anything I throw at it.

What Makes it Special?

This particular tool goes above and beyond even a standard jack plane thanks to a very important feature: the bevel-up design. By orienting the bevel up, we can use multiple blades with different bevel angles to change the behavior of the plane. There are also some other unique blades available that increase the functionality of the tool. Here’s a quick rundown.

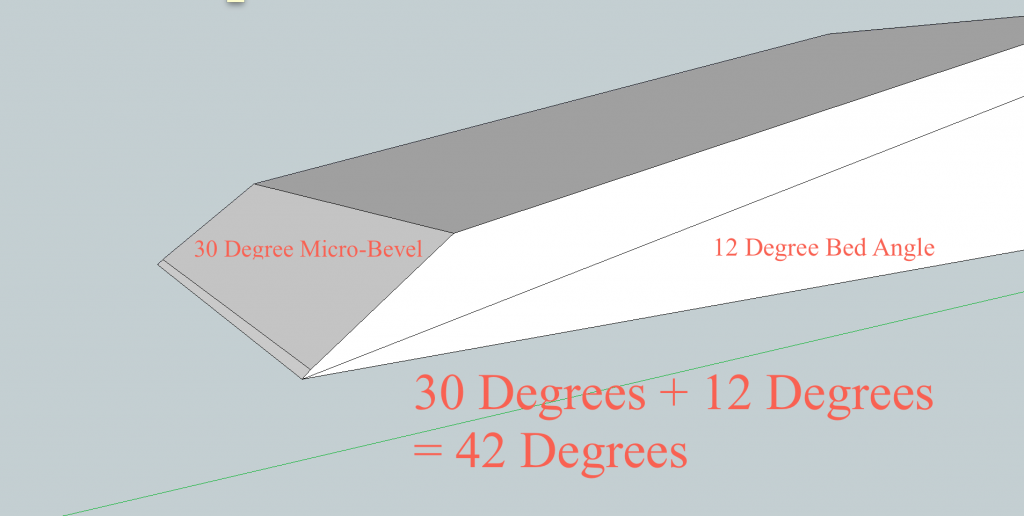

Blade #1. 25-degree bevel with a 30-degree microbevel. With the bed angle of 12 degrees, this gives us an effective working angle of 42 degrees, which is very close to a standard bevel-down plane (45 degrees). I use this blade for general planing of easy-to-plane woods as well as end grain.

Blade #1. 25-degree bevel with a 30-degree microbevel. With the bed angle of 12 degrees, this gives us an effective working angle of 42 degrees, which is very close to a standard bevel-down plane (45 degrees). I use this blade for general planing of easy-to-plane woods as well as end grain.

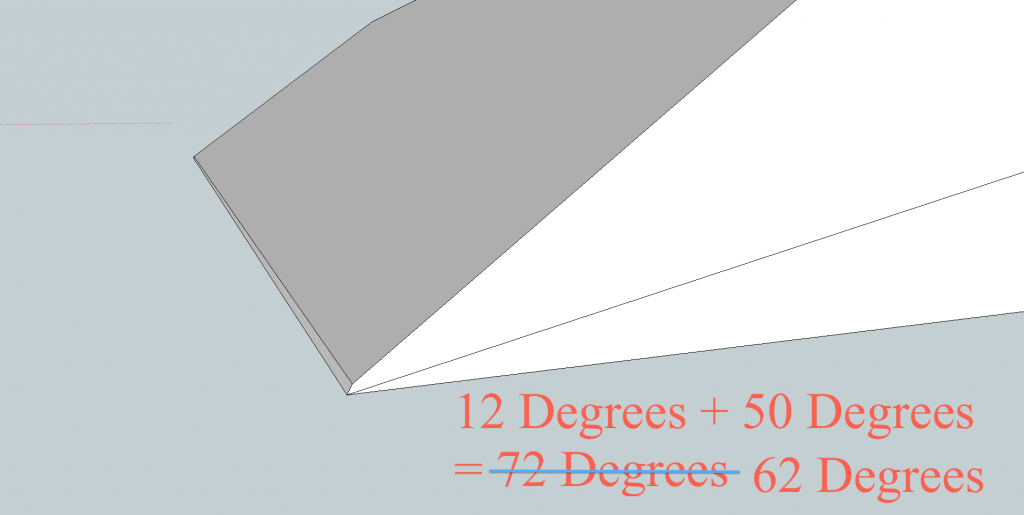

Blade #2. 25-degree bevel with a 50-degree microbevel. With the bed angle of 12 degrees, this gives us an effective working angle of 62 degrees. This high angle makes it possible to get clean cuts on gnarly, unforgiving and figured woods. The cutting action itself is close to scraping so there will be little chance of tearout.

Blade #2. 25-degree bevel with a 50-degree microbevel. With the bed angle of 12 degrees, this gives us an effective working angle of 62 degrees. This high angle makes it possible to get clean cuts on gnarly, unforgiving and figured woods. The cutting action itself is close to scraping so there will be little chance of tearout.

Blade #3. A toothed blade is good for roughing. The teeth allow you to take deep cuts without getting tearout. A great blade for those who want to mill rough boards by hand, or when you have a wide board with excessive twist. You can knock down the high corners and then send the board through a planer to get it nice and flat.

Blade #3. A toothed blade is good for roughing. The teeth allow you to take deep cuts without getting tearout. A great blade for those who want to mill rough boards by hand, or when you have a wide board with excessive twist. You can knock down the high corners and then send the board through a planer to get it nice and flat.

Blade #4. A 90-degree blade for scraping tasks. It essentially turns the jack plane into a scraping plane.

Blade #4. A 90-degree blade for scraping tasks. It essentially turns the jack plane into a scraping plane.

Demo

In the video at the top of this post, I show you the results planing long-grain and end-grain cherry with the 30-degree blade. I then plane some highly figured maple with the 30-degree blade to show that there’s a good deal of tearout. With the 50-degree blade installed I plane the same figured board with glass-smooth results. I then use the toothed blade to flatten the face of a rough mahogany board. Later, by request, I show how the #7 jointer plane, with its standard 45 degree angle, also produces a fairly rough result on the figured maple board.

Money

To help put things in perspective, I am using brand new retail values from Lie-Nielsen.com. Let’s assume this plane replaces all the following items:

#5 jack plane – $325

#7 jointer plane – $425

Smoothing plane – $325

Scraper plane – $215

High-angle frog – $75

———————

Grand Total: $1365

To get comparable functionality with the low-angle jack plane, the breakdown looks like this:

Low-angle jack plane – $245

50-degree blade – $40

Toothed blade – $65

90-degree blade – $45

———————

Grand Total: $395

Conclusions

Obviously, we have to make a number of assumptions here and this plane will not be right for everyone in all situations. It’s a compromise solution and it could very well fall short depending on how you work in your shop. Also keep in mind these prices are for reference only and you could find much better prices in the used market or with other brands.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Can the Low Angle Jack Rabbet Plane be used in the same way?

Thanks,

Joe

PS Always enjoy your vids–informative and fun.

The Low-Angle Jack may be the only BENCH plane you need, but don’t forget that “little” jack-of-all-trades, the low-angle BLOCK plane. Those MIGHT be the only TWO planes a HYBRID woodworker would ever need, but certainly not the only one you’d ever want.

Take a look at Chris Schwarz’s tool box. A #5 Bailey, Block Plane, Moving Fillister Plane, and a rack of rounds and curves, which could be replaced by a Stanley #45 if you don’t mind the endless fussing. Still, I’m confident his #5 and block planes do 80% to 90% of the work.

Steve Jaynes

“The only handplane you need?” The answer to this question, of course, is No. Millions of woodworkers get along fine without a low angle, bevel up plane. That type of plane has always been very rare until today. So the chance to find one on the second hand market at a nice price is low. At the other hand, Stanley #4’s are equally capable to deal with everything a powertool user could ask from a handplane, and they are a dime a dozen. How to deal with difficult grain is allready explained in the April 2014 issue of Popular woodworking magazine, learn to use the chipbreaker. The Stanley #4 handles all issues that the bevel up can handle too, without the need to buy extra blades. It is a lousy jointer of ocurse but that’s the same for the LN 62. And you’d like a cambered blade to be able to use it as a jack plane, but powertool users probably don’t have much need for that either.

So the only plane you really need is a Stanley #4. It can even replace many block plane duties.

Please learn more about the history of English and tool names. The “jack” in a jack plane refers not to “jack of all trades” as you suggest, but rather to the fact that this particular plane was a diminutive (smaller) version of the full size version of this tool now known as a joiner. I am sorry to say that tool manufactures and sellers alike usually use the term “jointer” today. But this term is incorrect as reflected in the name of the “United Brotherhood of Carpenters and Joiners of America”. I was a joiner, and used a joiner plane, not a “jointer”. Just because everybody makes this mistake don’t you do it also. Joiners flattened rough timber and sometimes connected it at joints. Carpenters (originally a cart or chariot maker) put together rough sawn or hewn (axe) lumber into structures (think timber framing). A “jack” is a smaller version of anything; a “jack” is the smaller (younger) version of the king in a deck of cards, the smaller flag on a naval vessel, the smaller version of many animals. Block planes are so named because they are intended to finish the working surface of butcher blocks which is always end grain not because they are the size of a small block (as I have read some people describe them).

Another issue is how often you want to be changing irons. As a hand tool user, when working stock up for a project, I change hand planes numerous times during the process. It’s pretty much an imperative to be able to just grab what I need and begin using it without fussing around with the iron settings.

Of course, if you are primarily a power tool user, this wouldn’t be a big deal as your hand plane use would be limited. Most of what you are using the smoother, high angle, toothed, and 90 irons for would be done with planers and sanders.

That is one to look at it and it works if you only wanted one plane. Yet if you want to make a living at it then this is not the choice. I can also say you can get great users with irons for less $395.00. For that price I can get a 4,5.7, Toothing plane, and Stanley #80. How do I know that? Well I just bought a set for a student who is wanting to get into the craft. I guess I might be lucky since I live in New England. Thanks for sharing.

I couldn’t agree more. My LN62 is my favorite plane. I’ve been preaching this same mantra for years.

Lower the cost by about $20 by getting a vintage #80 instead of the scraper plane. They have come back to Earth in their pricing at $25 to $30 if you are patient.

The individual plane price list above can drop $75 be eliminating the extra frog if you are willing to do a little bit of modification to the LN cap-iron.