We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

One of my favorite finishes is Watco Danish Oil. I love the product, but hate the container. In addition to being a pretty good wood finish, Watco Oil is also a very effective metal-to-metal adhesive. After you use it, the little bit of finish that drips around the threads of the opening gets spread around when you put the cap back on. By the time you need it again, the oil polymerizes making an incredible seal between cap and can. I’ve been using Watco so long that I remember when they added to white “safety cap” to the lid, a move that made a bad situation worse.

One of my favorite finishes is Watco Danish Oil. I love the product, but hate the container. In addition to being a pretty good wood finish, Watco Oil is also a very effective metal-to-metal adhesive. After you use it, the little bit of finish that drips around the threads of the opening gets spread around when you put the cap back on. By the time you need it again, the oil polymerizes making an incredible seal between cap and can. I’ve been using Watco so long that I remember when they added to white “safety cap” to the lid, a move that made a bad situation worse.

As you can see if you click on the photo to enlarge it, the lid tells you to push down as you turn to open. That’s a lot like telling you to use a pulling motion to put the cat in the carrier to take him to the vet. It’s not the direction either one of you want to go. About fifty per cent of the time I can get a fresh-from-the-store can open by hand but after that, I have to have some help. I refer to the dedicated tool I use as the “Watco Can Opening Pliers”, but most people use a different term.

I keep this small pair of Channel Lock pliers around for the sole purpose of opening Watco cans, and I can’t remember the last time I used them for anything else. This size is just big enough to get around the cap, and bigger pliers are more effective but these don’t take up much space in my pinching and grabbing things drawer. Sometimes, if the lid is stuck on really tight, the pliers will break the bond between the plastic safety cap and the real metal cap. That’s a good thing. If you use the gallon cans, you’ll need to step up in size. My bigger pair stays at home where they serve double-duty; opening cans and tightening up the hose connections on the washing machine.

I keep this small pair of Channel Lock pliers around for the sole purpose of opening Watco cans, and I can’t remember the last time I used them for anything else. This size is just big enough to get around the cap, and bigger pliers are more effective but these don’t take up much space in my pinching and grabbing things drawer. Sometimes, if the lid is stuck on really tight, the pliers will break the bond between the plastic safety cap and the real metal cap. That’s a good thing. If you use the gallon cans, you’ll need to step up in size. My bigger pair stays at home where they serve double-duty; opening cans and tightening up the hose connections on the washing machine.

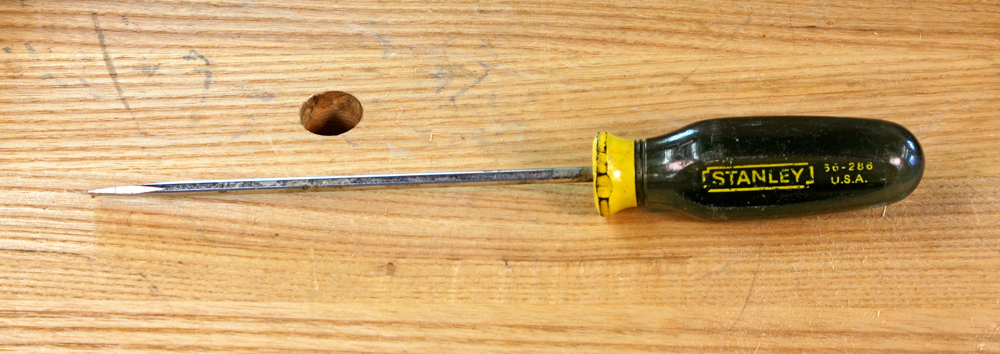

So I got to wondering: What tools do you keep around that only do one mundane task around the shop? Leave a comment below to share your favorite. I have a few such tools, and I wonder if any of our readers can guess the purpose of the skinny screwdriver with the long shank in the picture below. Leave a comment with your guess, and the old-timers will have an advantage here. This screwdriver was made obsolete for my purpose in the woodshop about 15 or 20 years ago.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I like Ricks Idea of a cheap chisel. I have a similar tool I use for much the same purpose. I bought a gasket scraper from an automotive supply. It has a screw driver like handle and a 1″ wide blade that I use to pry with, scrape glue out of corners etc. It isn’t as high a carbon steel as a chisel so it isn’t quite as brittle and is easy to sharpen.

I have a tool that’s a must-have for every woodworker: a cheap chisel. Years ago the term would have been “cheap Sears chisel”, but nowadays such a chisel might be from India and not Sears brand.

I use it for all the miscellaneous jobs that I might otherwise be tempted to use a real chisel or screwdriver for: scraping paint, prying nails, prying out the metal plug that seals a new can of paint thinner, and so on. Never for cutting wood: I have real chisels for that.

Calling it a tool might be a stretch, but one of the workshop items I use most frequently is a wooden glue-bottle opener I made many years ago. This wasn’t an original idea, but I have no idea where it came from. It’s sure been useful, though.

It appears that the screwdriver is used to remove the plastic safety cap so one can get to the metal cap easier. I remove the safety cap from all of the cans the first time I open them. I do this by cutting slits in the plastic cap with a utility knife and slipping a narrow screwdriver between the plastic and the metal to remove the plastic totally. It is never a problem removing the cap after that. Some may have children in the shop that the safety cap is intended to protect. The best way to minimize the problem is to clean the threads with mineral spirits before replacing the cap. Hope this helps. EarlS

When I saw the picture of you opening the Watco it’s similar to my shop until this trick I’d like to pass on to you and others. First off, get rid of that crappy little white plastic top which is easy to do with that big Stanley screwdriver (yep, I have one too).

Here’s the trick — Teflon Tape! Simply wrap a turn or two around the threads of the can and you’ll be able to open it easier. I mix up small batches of shellacs, toners, etc. and use this on mason jars as well. Doesn’t hurt to wipe the threads in the cap and on the jar first with a rag but the Teflon Tape keeps them from sticking.

Allen wrenches….so many shop tools have hexagon drive nuts that I put the correct sized Allen wrench on the tool that requires ’em. Usually I attach them using one of those tiny nickle plated magnets.

I once cut off the bent part of an Allen wrench to make it chuckable into a drill so I could drive hundreds of the same sized ones in a power tool I was assembling….saved me busted knuckles and hours (lol)

My favorite one use tool is my Park Tools bottle opener. It’s great on paint cans!

http://www.parktool.com/product/bottle-opener-bo-2

I ditch the plastic cap and use water pump pliers on future metal cap openings. I wipe the cap and can threads each time I close it.

I collect the old lady’s used cleaner spray bottles for “decanting” Watco Oil and for a jug of mineral spirits. When I spray some oil finish – good for careful control of the amount – the pump gets moved to the mineral spirits jug and a few pumps gets it cleaned out pretty good. And the clean pump gets left on the mineral spirits; the “old” pump from the mineral spirits jug goes onto the oil finish jug for the next coat. Also have one for pure tung oil that I use on surfaces that can’t take the eventual darkening of the linseed oil component in the Watco oil.

Tried a sprayer for a mix of tung oil and resin varnish, but it didn’t clean well and would spit gobs of finish on the wood that were irritating to deal with.

I use a flat head screw driver to pop off the white plastic thing. Underneath is nice regular metal cap that has a knurled top that is suppose to lock onto the knurls on the plastic cap. With the white cap gone it opens nicely.

Scott

I use a pair of metal nut crackers on stupid tops like these they work well on these royal pain in the butt. When they get very tight I cut away the plastic top and fit a used wine cork instead those with a plastic top as found on sherry bottles work best. I keep my bulk shellac in reclaimed sauce jars and the metal lid always sticks to the glass and I use a bottle opener to ease the lid.

I learned a neat workaround for the Watco Cap Challenge. Forget the cap. Punch or drill a small hole through the top of the container in the opposite corner. Then screw in halfway a #10 or #12 woodscrew. The screw will self thread and form an adequate seal. The hole is large enough to pour out your oil, if you’re a wee bit patient. Easy to open and close the screw seal with your fingers, so no need for channel lock pliers. Enjoy!

I have the exact Stanley screwdriver as that pictured. I use it to puncture the inner metal seal on cans similiar to the can pictured. Also good for the glue containers when they harden from lack of use.

+1 on the waxed paper. Always waxed paper around the shop for isolating clamps and cauls from glue. Plus I remove the plastic trick immediately by cutting it with a utility knife.

Someone has ground that screw driver to make an awl I would say

I hate those cans, too. When replacing the cap I place a piece of wax paper between the cap and can. It gives a better seal and it’s easier to remove the cap the next time.

Dang, I thought I was the only one with one of those old saws. Bought mine new, and wished all of these years I’d waited until their next version, where the screw driver was no longer required! If someone borrowed “that” screw driver, I was shot. Haha.

This isn’t about a tool, but rather about the Watco can and preventing it from being sealed shut.

When I first open a can I wrap the “nozzle” with teflon tape. This puts a barrier between the metal parts and the Watco does not stick to the tape.

I do have to occasionally replace the teflon tape, which is sort of a hassle since it has stuck to istelf.

I have a pair of sheet metal bending vise grips that I use only for removing Festool dominos during test fitting dry assemblies. I keep it in the Systainer with the Domino.

While I have myriad allen wrenches, I have one about 12″ long with a clear plastic yellow handle that is dedicated to attaching and removing the plunge base from my PC 690 router. The handle has just the right mass to smack the top of the allen screw after I’ve loosened it, to release the cam and wedge.

I use dowels a lot. When I use them for jointery I always test fit everything together before glueing, getting them out without destroying them is the tough part. I was given a pair of these http://www.amazon.com/Lisle-52990-Spark-Plug-Pliers/dp/B001PN88NC/ref=sr_1_1?ie=UTF8&qid=1334273982&sr=8-1 by my father-inlaw several yrs back because they didn’t work for him-made my life a lot easier!!

The screwdriver looks like the one I use to secure the blade in my Bosch jigsaw.

Ray

I also have a wrench under the table just for opening Watco products. I can’t believe I’m not the only one.

And I have a screwdriver-looking tool that I use to break the seal inside caulking tubes and to poke holes in the skin that develops on top of certain varnishes after the can’s been opened.

And I keep half a baseball bat (fungo bat, actually, left over from my coaching days) as a — you guessed it — wooden mallet.