We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I built my Roubo clone frame saw many years ago after seeing a similar one in Colonial Williamsburg’s Hay shop. With my version, which is a closer approximation of the Roubo saw in both style and blade geometry, I attempted to improve on some of the slow cutting attributes of the Hay shop’s saw. Now some four years later, I’m realizing these saws really don’t work that well. They certainly aren’t a quick and easy tool for resawing. And producing hand cut veneer (below) is a feat of skill and no doubt specialty tooth-filing very likely beyond the capabilities and patience of normal woodworkers.

I just want to bring a few details to your attention:

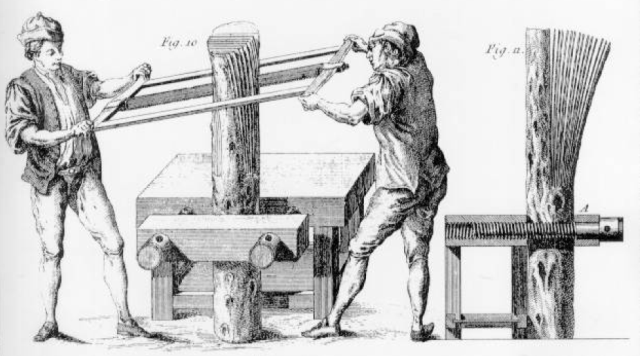

1) The log in the picture really isn’t that large. And most of the cuts through the sap will very likely result in unusable material. If true, why would anyone make those cuts? Is it possible this picture is merely illustrating the concept and not an 18th-century snapshot of actual work? (btw: notice the toe-pointing first-position stance of these craftsmen – hard to believe any self respecting woodworker would stand this way, even if they are French. Got to be some artistic license here. We are brothers all.)

In general, when sawing thin stock, the saw cut will wander to the weak side. When I cut thin stock (or even rip a small amount from a board), I find a way to support that waste. Failing that, its always best to resaw in halves. I would have started these cuts in the center, then split the subsequent cuts.

Also, regardless of the tension placed on the blade, a thin piece of sheet metal cannot react to any torsion whatsoever. In use, these saws twist in the kerf, follow the path of least resistance, and are generally difficult to control.

2) Has anyone seen one of these in an English shop? I’m not talking felloe saws, the short frame saws made popular by Windsor chair makers years ago (who I suspect exaggerated their resawing capabilities). The large frame saw we have seen images of always come from French sources. Remember that French craftsmen didn’t generally have English panel saws in the 18th-century.

My experience is that resaws of 12″ or less are better, faster, and more easily handled with a coarse toothed panel saw. Resaws over 12″ are best handled at a mill.

3) My ham-fisted babel fish translation of Roubo went somewhat like this: When the work is small, [the cabinetmakers] do it themselves. Otherwise they send the work to the mill. (Isn’t that what I said my experience was above?)

Remember that 12″, 18″, 20″ resaws are what pitsaws were for. I think a good, motivated team could saw 1″ per minute. “Maybe faster,” says Roy Underhill. I can rip 1″ per stroke with a hand saw through 4/4 stock. Perhaps this many-times made public admission has set an unrealistic level of expectation.

I hate to produce a negative-sounding or discouraging post. But I feel strongly that I may have misled folks into thinking these saws are reasonable approaches to resawing thick material by hand. After four years of trying and refiling, I now believe they are not. Nor do I believe that historically they were fantastically productive tools.

One more word of caution: There are a lot of people making saws, filing saws, selling parts or kits of saws that really aren’t optimized for the intended job. To make saws well, you have to have done more than a few test cuts with them or asked one man’s opinion. Beautifully sculpted handles and shiny blades won’t help you saw dovetails for four or six hours. Likewise, there are many satisfied customers raving about saws that I don’t think work well. Though I would never want to be accusatory, I wonder how many folks are responding after some significant use of the product, or do they open the box, make a test cut, then post to a wood forum. Without taking a poke at anyone, beware.

My approach to designing and making hand saws (I’ve made many) was to make prototypes, sometimes many prototypes, and test them in real world conditions over a period of years. Let’s call this post the end of one of those test periods. I would not offer my version of this saw for sale because I don’t believe it would meet the expectations of woodworkers who have access to good quality panel saws. For the 18th-century French workmen, it may have been an improvement over what they had. For us, these saws are not.

100% honesty –Though I’ve always found a way around it (and never used one), I think a large resawing bandsaw looks like a good substitute for a pit saw operation. I would not be embarrassed to have one in my “hand tools only” shop. I doubt it would be the end of my hand sawing days. And pit sawn lumber looks like band sawn lumber (except the pit saw marks are at a slight angle from perpendicular). In the same breath I make this uniformed recommendation, I recall my own advise to listen carefully to those with practical experience. I invite you to help your fellow woodworkers here and now. Can you resaw 16″ wide 8/4″ boards into 2, 3/4″ boards on a band saw? Do you need a special band saw, band saw blade, sled or outfeed rollers? What does it take to resaw wide lumber with modern machinery?

Last word: I apologize to those I’ve inspired to make these saws, and who later found out they didn’t work quite as well as I hyped. (No, I didn’t misspell “hoped”).

– Adam Cherubini

Check out Adam’s many, many projects and PDF downloads at ShopWoodworking.com.

Check out Adam’s many, many projects and PDF downloads at ShopWoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I have not resawed 16″ anything. I have sawed quite a bit of 8″ hardwood on an old two wheel Tannewitz.. Power tools have taken the place of the 19th and earlier century’s apprentices. Leanardo would not have given up his apprentices, and he would have delegated most of that hand tool work to minions.

I have lots of those trendy tools that I have bought over the years, because of the flashy ads, most have fallen by the way side. Bow saws fell out of favor, when they were replaced by saws with more steel, that cost more, but proved to be worth it.

In the light of Tom Fidgen’s kerfing plane and frame saw is it worth exploring a different approach?

You wrote about the saw “follow[ing] the path of least resistance”. You could help it along with a kerf all round.

This might not be period-correct but it does seem to work.

I’m reposting here because I keep getting emails from people asking if I have read this post. I respect Adam’s opinion but I have to wonder what good comes from discouraging someone to try building one of these saws. I have now put a substantial amount of time in behind both my 48″ and 36″ model of this saw. I have cut 1/8″ thick veneer and 1″ thick slices from everything from 6″ wide up to 24″ wide. I have cut Basswood, Cherry, White Oak, Walnut, Afrormosia, Teak, Pine, and Hard Maple. There is a big learning curve to guiding this saw but nothing that a little practice won’t correct by going and buying some cheap 2×12 home center stock and making cuts. You have to fiddle with the set a lot more on this to get the entire blade running true, but 9 times out of 10 errors in tracking a line relate to body mechanics because the long stroke of the saw amplifies and misalignment in your stance and arm movements. Practice figured this out for me and my own technique eccentricities. I stand by this saw as an element that has changed my woodworking! I have possibilities with it that I would not have with a Bandsaw because I will never have the space or money for something that can resaw a 20″+ board. I have shot several videos on this saw if anyone is interested. http://www.renaissancewoodworker.com/why-you-need-a-resaw-frame-saw/ is where you can find my results of a recent 24″ wide board and a short video. Plus you will find another video in the related links at the bottom. I hope people will reconsider and make this saw, it is a great learning experience in sawing technique, saw sharpening/setting, and will open up a lot of possibilities lumber wise in your work.

I feel a little late to the party, but as someone who resaws on a regular basis with machines, I feel I can shed some insight. I never up and cut logs. Sometimes customers bring logs in for furniture, if they have special meaning, but they are always sent off to the mill. My first step is not the bandsaw, it is the tablesaw. It maynot cut all the way through, but it is fast and will leave a deep kerf on both edges which the bandsaw will track in. It cuts down on the time it takes for the bandsaw to cut and allows you to not worry about special blades, fences, etc. Much faster, and since getting projects out the door is my sole source of income, That is very important. I can’t imagine the headache of just throwing a 15″ board up on my bandsaw and expecting it to come out good enough to use in a timely fashion. This means that boards under 9 inches are resawed solely on the tablsaw. hope this helps.

Just thought I’d point out that resawing 16-inch-wide stock will take a pretty serious bandsaw. Most saws (even decent ones) will only do 12″.

If buying new you’re spending $3000 on a Laguna or $2500 on a Grizzly before you get that kind of capacity.

The reason that we made these saws was to find out how they work. It seems that most people are having similar results but we are all using narrow blades as far as I know. the originals had blades with around .050 thickness and 4 inch width. I would assume that these wider thicker blades would have less of a torsion problem. I also wonder if our frames are rigid enough or if they are also twisting in use.

If these saws didn’t work they wouldn’t have made them.

Are they necessary? Probably not, fun to mess with? absolutely!

Remember that there was no alternative back then and these guys were more skilled and in better shape than most of us.

I plan to make some wider blades and experiment some more. Not everything works perfectly right out of the gate.

This is pretty interesting. I am curious about your “coarse toothed” panel saw to which you compare the performance. How coarse? Am I wrong it thinking that it does seem logical that panel saws would have advantages as they eventually replaced frame saws?

My history can be sketchy, so even for pit-sawing, I am curious about the timing of the transition from frame-type saws to “panel saws”. You are saying that transition happened in England first?

Regardless, this is why building and trying tools like this is educational. But, I am always more interested in the journey than the destination… No one seems to think these saws are “quick and easy”.

Great post Adam. I am one of those that have made a saw like this though I admit it was Mike Siemsen who led me “astray” and not you. I essentially have the same saw at Bob above and I have written nothing about it yet for fear of being one of those you mention who write without significant testing. I can count the number of rips I have made with the saw (finished a few weeks ago) on 2 hands so my experience isn’t very deep yet. So far I really like it on 12″ and narrower stock. Like Bob said, I prefer it over my 5 ppi 28″ hand saw. I made one attempt on some 10/4, 15″ wide Sapele and it was definitely hard work (made worse by the hardness of the species)and steering was tough but still I started the kerf accurately with a lower pitched saw so the good start helped a lot. In all of the above cases though I was essentially halving the board and this may attribute to my favorable experience. The only time I have cut veneer thicknesses were on 2 occasions with a 5″ wide board that was 12″ long. It was very fast and I did get some deviation. However the shorter length meant that the deviation didn’t make too much difference. I think the final use of the sawn board needs to be considered. Are any of us making case sized veneer in our shops or are we just cutting drawer fronts? Probably the later and more than likely the resawing of larger stock is to make solid wood panels. In this case like I did, we are halving the stock and this saw (so far) works well.

However, I am about to do some field testing of some different widths of blades to include 3 and 4″ which may be interesting on the torsion front.

I’m sure the Roubo saw would work fine if you had a partner to help you saw. I do not, so I’ve never made one. All of my resawing is done with, as you say, a coarse handsaw. It works just fine.

Despite your disappointment, it is good to see a thoughtful report of a long-term experiment. I am curious about how often you used this as a two-man saw, and if you were able to work with the same partner regularly when sawing.

I haven’t done a great amount band saw resawing, but since no one else is biting I will admit to having resawn 16″ mahogany, 12 feet long on a band saw with a minimal (perhaps some would say, very sub-optimal) setup: shop made high fence, 3/4 inch, 3tpi skip-tooth blade, one man feeding and another supporting the outfeed. This was done on an old Davis and Wells 20″ band saw, which is is heavily built and runs very true. When the blade was fresh it worked quite well, although one had to be patient, but when the blade dulled we lost control quickly. Nowadays I would prefer a carbide toothed, dedicated resaw blade, but I think that a well-tuned saw and a sharp blade are the essentials, together with some sort of outfeed support for long pieces, either a table or a second pair of hands.

Excellent post. Over the past couple years I’ve resawed some maple tree trunks by hand, and it was difficult but not impossible. Similar to Mr. Maxwell above, I used an old Disston #7 28 inch 4pt rip saw (Ebay, $50) that I sharpened. As an example, a 16 inch diameter by 36 inch length maple trunk section took about 3.5 hours to rip in half. Part of the challenge was securing the log while cutting – I used two Swartz saw benches to support it, albeit not very well. I’ve thought about building one of those Roubo benches shown in the photo above with a large-throat vise.

After making the initial rip cut (which did end up having some twist in it near the end of the cut) I took the 8 inch thick halves to my band saw for further rips. When I purchased the bandsaw, it came with a 6 inch riser block which allowed for a 12 inch throat. No sled, no rollers, just a friend to help support the wood (it was heavy). I used a 5/8 inch 3 point timberwolf resaw blade which cut the maple well, but the going was slow largely because of wet/green wood, and 120 volt running in my garage: P = IV, so 240 volts would give you twice the power given unchanged current. If you have the ability to rewire to 240 volt, that would be my suggestion. My friends thought I was crazy, but it was fun and a great learning experience. Now I have a bunch of maple air drying…

I don’t know. I still like mine better than a regular hand saw for wide stuff, like more than 8″. I just did some 10″ wide walnut and it took only about 12 minutes to do about a 3′ length. I think it’s more in the teeth than the style of the saw though. Mine has just over 2 teeth per inch. Perhaps if I had a 30″ hand saw with the same tooth spacing as my frame saw I might feel differently, but is imagine a saw like that would tend to want to kink if it wasn’t made from a real thick plate. I think compared to most people’s experiences using 5 and 6 point rip saws, these are an improvement. However, I do agree with you that they still aren’t easy. They’re near impossible to correct if they go astray, which can happen easily. And they still require flipping the board occasionally and sawing in from all four corners to do a decent job. If you can get it to start well though and keep it relatively level, at least mine tends to track relatively well. Is it the same as a bandsawn cut? No. Is it still a lot of work? Absolutely. I’m not ready to go back to resawing with a 5 point saw though. At least not for the wide stuff. It would be nice at times to have that resawing bandsaw with 18″ capacity though. It is a workout to do.

This is very interesting, as common wisdom seems to be that the Roubo frame saw is the cat’s hind end for resawing, and I’ve been curious to make my own and try it out. Maybe I’ll prod the oldtools list to check this post and debate :).

Personally, I presently do all of my resawing and ripping with vintage handsaws, as I no longer have a tailed saw. It’s pretty straightforward, though I’ve never resawn anything over 12″ wide, and never tried veneer (typical product is 1/4-3/8″ for me). My favorite saws for that are 4-1/2 pt, 28″ Atkins and Disston products, though I use a finer one for some stuff. I really notice a dull or underset saw when resawing.