We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The “Swiss Army” family of knives, and their contemporary descendants – the Multi-tools, are a good solution for on-the-go situations. Although these tools can never really be a perfect substitute for the ergonomics and efficiency of the individual tool, their compactness and versatility can provide us with reasonable solutions while away from our shop, on the road, or when we can’t afford to buy too many individual tools.

The “Swiss Army” family of knives, and their contemporary descendants – the Multi-tools, are a good solution for on-the-go situations. Although these tools can never really be a perfect substitute for the ergonomics and efficiency of the individual tool, their compactness and versatility can provide us with reasonable solutions while away from our shop, on the road, or when we can’t afford to buy too many individual tools.

While preparing for my up-and-coming online woodcarving class at Pocosin Arts School of Fine Crafts I decided to try a multi-tool for carving and see if I feel comfortable recommending it to my students. As part of the class, I intend to talk about the tools of the trade, and while most of my students will certainly use a traditional carving knife, I thought that it is wise to mention the multi-tool option. Those “Swiss Army” folding pocket knife assortment of blades includes a knife and a few gouges in a narrow spectrum of width and sweeps.

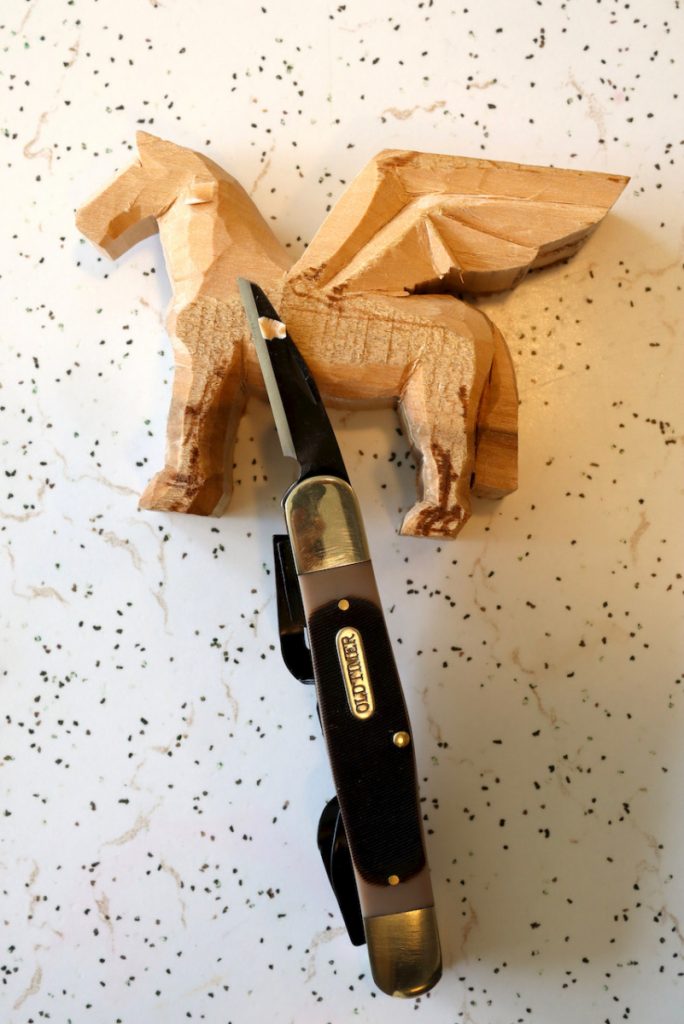

The most reputable (but also the most expensive) tool in this group is the American-made Flexcut Carvin’ Jack Folding Knife. While I am sure that it is a great tool, the price tag is just too high to justify a purchase by a first-time carver. The other tool to consider is a clone of the Flexicut that is made in China and goes by the brand name Old Timer 24OT Splinter Carvin’ 6in Traditional Folding Whittling Knife. At under $20 a tool, I thought that I should give it a try.

After my knife arrived, I took it straight to my sharpening stones, assuming that at this price point it was safe to assume that it is in need of some serious honing. I was not mistaken, as out of the box, the knife’s blades were dull. My first blade to be sharpened and honed was the straight carving knife. This is the most effective tool for whittling and the one my students will use during our class. After a few passes of the blade’s bevels on the stones, I noticed that one bevel was honed close to its ends (tip and base) while the opposite bevel was getting shinier at its midpoint.

After my knife arrived, I took it straight to my sharpening stones, assuming that at this price point it was safe to assume that it is in need of some serious honing. I was not mistaken, as out of the box, the knife’s blades were dull. My first blade to be sharpened and honed was the straight carving knife. This is the most effective tool for whittling and the one my students will use during our class. After a few passes of the blade’s bevels on the stones, I noticed that one bevel was honed close to its ends (tip and base) while the opposite bevel was getting shinier at its midpoint.

This bevel of the blade was honed close to its ends (tip and base).

On the other side, the blade was honed in the model. This was an indication that the blade was bent or cupped.

This was an indication that the blade was not straight and a sign of issues with manufacturing and quality control. To fix the problem, I tried to strengthen the blade by a “controlled bend” to the opposite side. I used a set of pliers and arched it until it straightened up. While doing so I felt that the blade resisted bending – a strong indication that it was made from good steel that was adequately heat-treated.

This was an indication that the blade was not straight and a sign of issues with manufacturing and quality control. To fix the problem, I tried to strengthen the blade by a “controlled bend” to the opposite side. I used a set of pliers and arched it until it straightened up. While doing so I felt that the blade resisted bending – a strong indication that it was made from good steel that was adequately heat-treated.

Once the blade was straight I resume the sharpening and honing using medium, and fine sharpening stones, and then finishing the job on a strop. I then tried the knife and found it very effective. The next blade that I honed was the chisel blade and later this month I intend to hone most of the other blades.

The Old Timer knife is a very affordable tool. Its construction and materials are pretty good, but you should take into account that you might need to work on it before introducing it to your basswood blank. If you are not deterred from fiddling with tools, then this is a good buy, but if you like to have a work-ready tool out of the box then I guess you should invest in the Flexcut knife.

A whale such as this, as well as other animals (check the images below), can be successfully whittled with only one carving knife. A traditional German-style shop knife can be a very effective tool for this job. A “Swiss Army” carving knife could also be a handy tool here. This knife’s other blades and gouges can be incorporated in helping us carve even more complex geometries and textures.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Mine came with a divot the size of #20 wire in the straight blade edge. I haven’t taken the time to try to hone it out yet.

Remember to wear your protective glove/s when carving and also – it is NOT a locking blade, it will fold over your finger if you slip.

The rule is: Always think about where that knife goes if it slips – and if it makes you queasy to your stomach, stop and figure out a different way of doing it.

RileyG, these are some fantastic insights! Thanks for sharing them with us.

In addition, a non-locking blade might be difficult to strop if the retention spring is not tight enough.

Best,

Yoav