We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

T-track is a versatile product that has many great uses around the shop. It can be attached to the fence of a chop saw, drill press or router table to provide a quick, secure place to attach feather boards, stops and hold-downs. It also makes a great addition to jigs and fixtures with parts that need to be adjustable or easily removed.

T-track is a versatile product that has many great uses around the shop. It can be attached to the fence of a chop saw, drill press or router table to provide a quick, secure place to attach feather boards, stops and hold-downs. It also makes a great addition to jigs and fixtures with parts that need to be adjustable or easily removed.

At first glance, all T-tracks look pretty much the same. There are, however, several subtle but important differences among brands.

Sizes and Prices

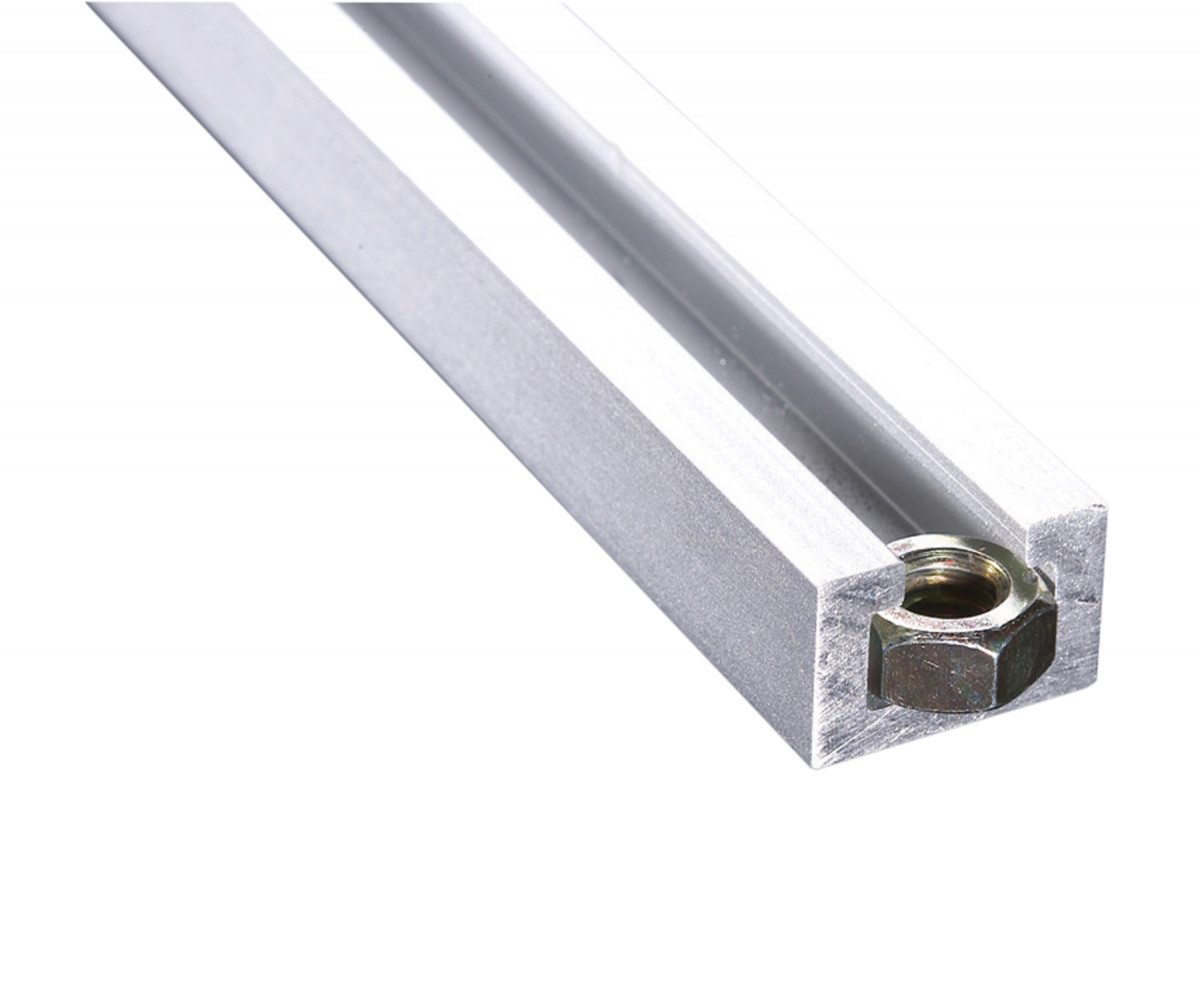

T-track is available in lengths from 1 ft. to 12 ft. and averages about $4.50 per linear foot. It is usually sold in 1- or 2-ft. increments, but some brands can be special ordered to a specific length. Most T-tracks are approximately 3/4“ wide with a thickness of either 3/8“ or 1/2“. Almost all are made of extruded aluminum. There are a few key features to look for.

We like T-track that accepts the hex head of a standard bolt. It will save you from having to buy the special connectors that some tracks require.

Accepts Standard Hardware

T-tracks that accept standard hex head bolts and nuts as connectors are a big plus, because standard nuts and bolts are readily available at hardware stores. This means you won’t get stuck in the middle of a project because you don’t have the right connector. Some T-tracks require special connectors that are only available from one supplier.

Some T-tracks have a deep slot to accept a hex nut. It’s a feature that will increase your connecting and fastening options.

Pre-drilled for Easy Mounting

We prefer T-tracks that are pre-drilled and countersunk to accept No. 6 or bigger wood screws. It’s also nice to have screw holes spaced no more than 5“ apart. Closely spaced holes mean more holes for more mounting screws and less risk of pulling the T-track off the mounting surface. Also, if you need to cut the T-track shorter, you will still have a hole near the end.

T-tracks pre-drilled to accept No. 6 or larger screws have better holding strength than the tracks that are drilled for No. 4 screws.

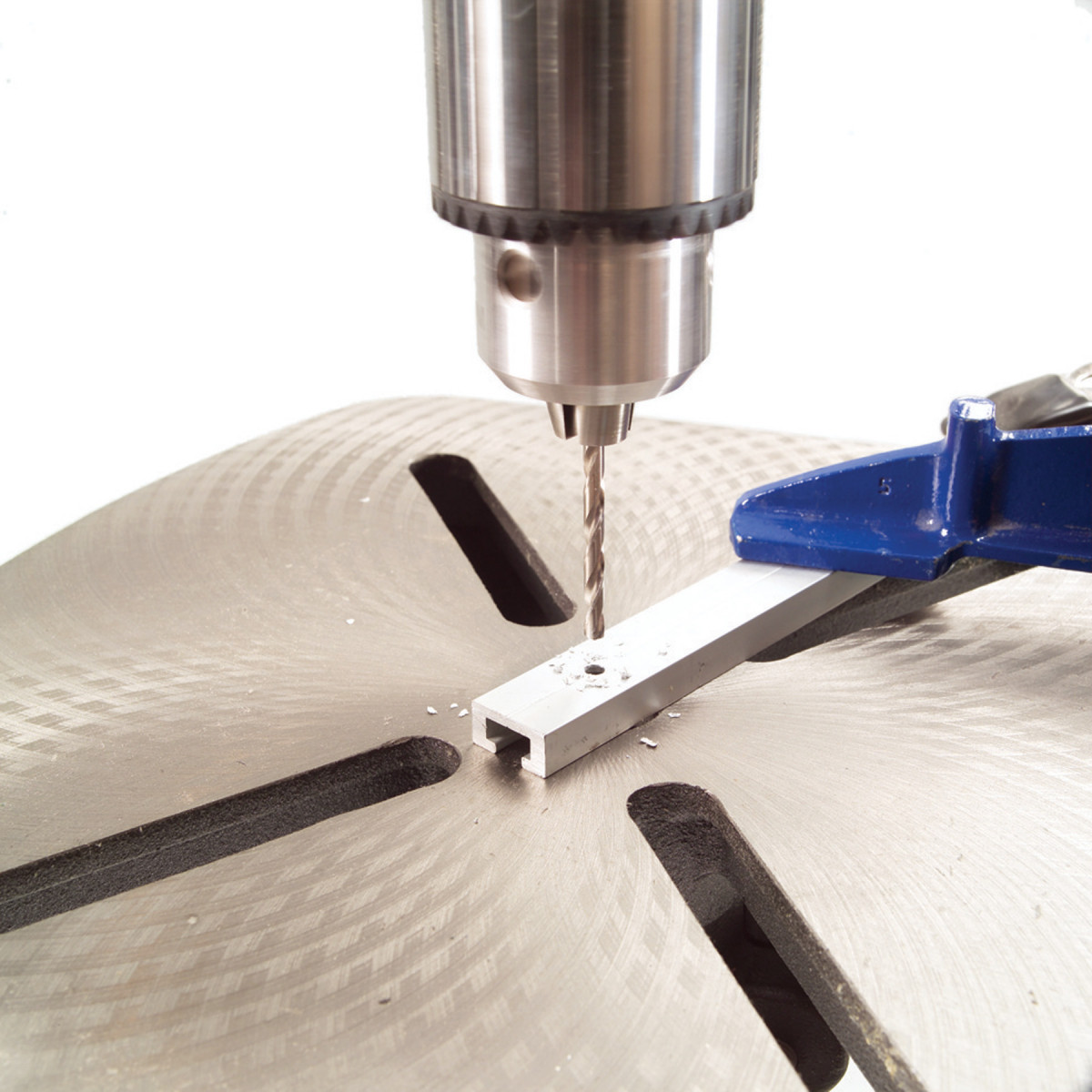

If you need to add screw holes to a T-track, you can drill them yourself. It’s a bit of a hassle but not difficult. Some T-tracks even come with a groove to help you center the drill bit. A groove on the bottom is best because drilling the shank hole from the top leaves a burr on the bottom that must be removed with a file.

Drill the shank hole from the bottom of the T-track with a 5/32″-dia. bit. Some T-tracks have a groove to help center the bit; it’s helpful but not essential. A pencil line and center punch also work well.

Make the countersink for the screw head with a 9/32″-dia. drill bit. Make the countersink just deep enough so the screw head is flush with the inside of the T-track.

Grooved for Glue

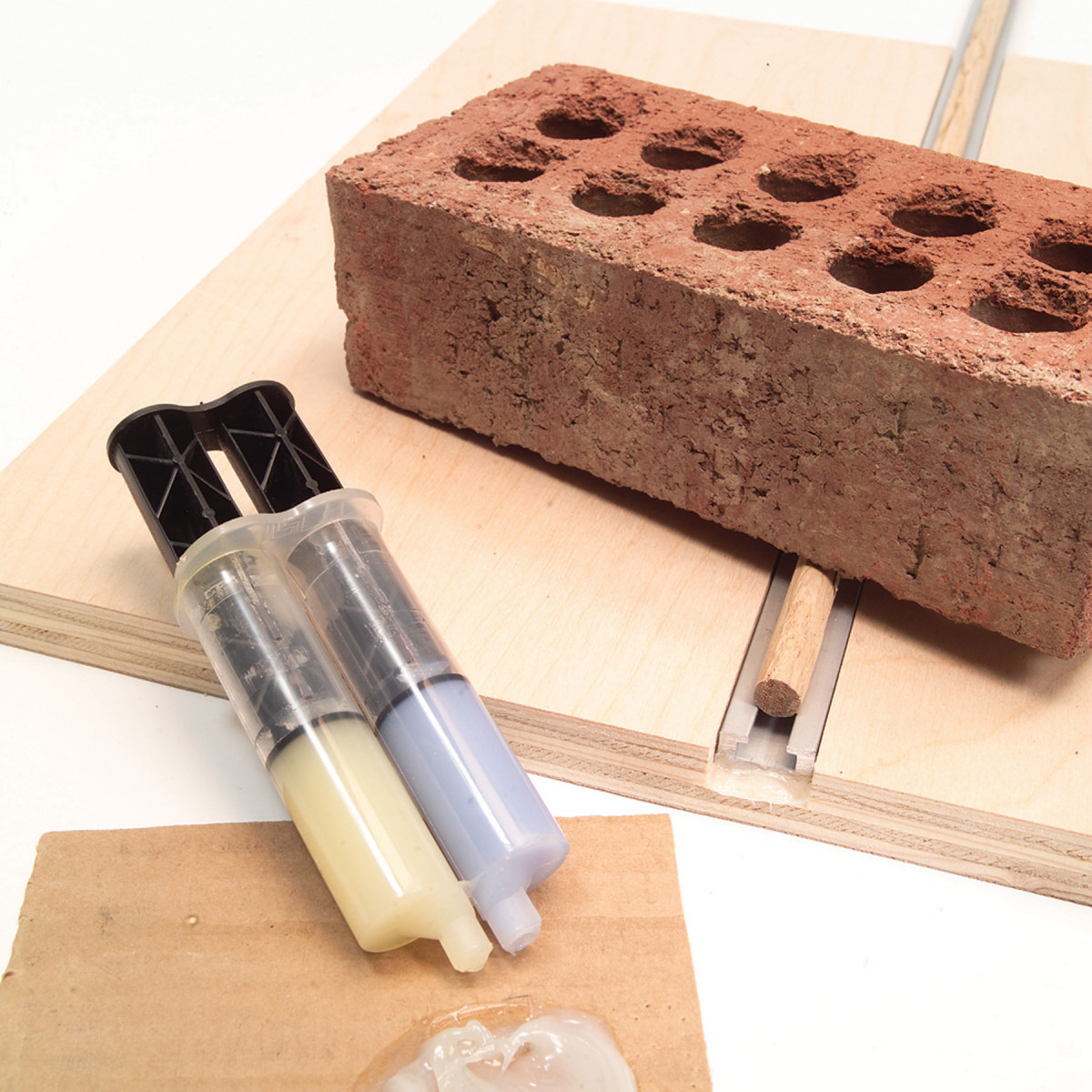

Glue grooves or lips on the sides of T-tracks provide a mechanical bond when gluing a T-track into a dado. Gluing is the best way to mount a T-track in a dado when the material below the dado is too thin to hold screws.

Glue grooves or lips on the sides of T-tracks help lock the T-track into the dado

Undrilled T-tracks have one advantage here: There are no screw holes for glue to squeeze up through. If your T-track has screw holes, just cover the holes on the bottom side with small pieces of masking tape before gluing.

Hold the T-track in place with a dowel and some weight when gluing it into a dado. Epoxy is the glue of choice because it bonds to both wood and metal.

Fits in a Miter Slot

Some T-tracks will fit into miter slots on table saws, bandsaws and router tables. Some T-tracks can be used with the slot up or down, while others must be one way or the other to get a good fit.

T-tracks that fit into miter slots make handy runners for sleds or jigs

The 3/8“-thick tracks are the best choice for use in miter slots. Thicker tracks will extend above the miter slots and you will have to cut a dado in the bottom of the jig you are making.

Specialty T-Track

Many woodworking tool and supply companies also sell a variety of special-application T-tracks. Some have multiple slots, unique shapes or even a built-in tape measure. One type is the miter-slot T-track, which is designed to accept the bar of a standard miter gauge. In addition to these specialty T-tracks, a huge selection of ready-made jigs and fixtures is available that you can add to your T-tracks.

Whether you’re building a miter saw station or a simple crosscut jig, getting familiar with the uses and applications of T-track will make your life as a woodworker easier.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.