We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

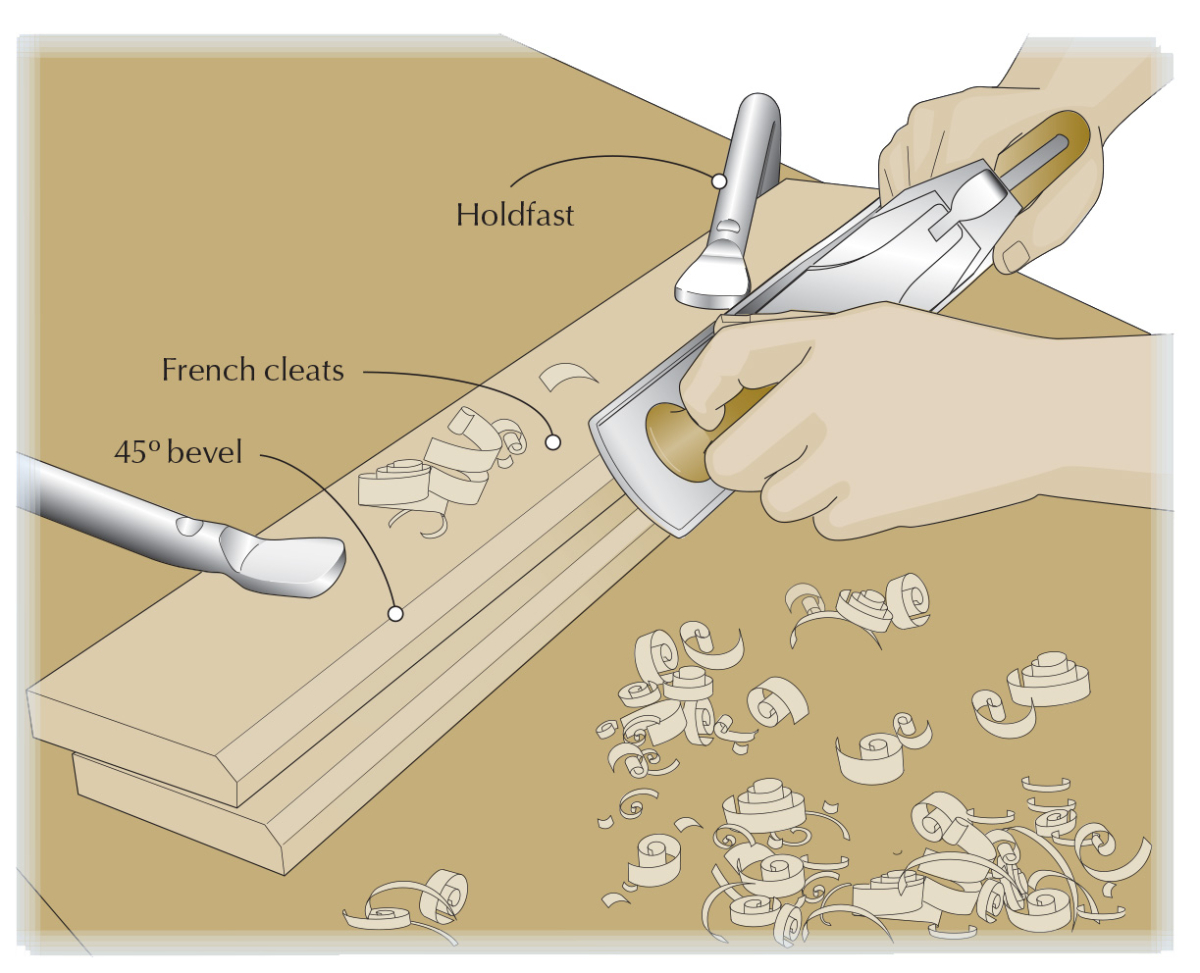

When making French cleats using a handplane, getting a consistent beveled edge can be problematic, particularly as the bevel approaches 45º and the plane gets “tippy.” Also, it’s difficult to get a good bevel established – starting on the small corner of the stock can be awkward.

When making French cleats using a handplane, getting a consistent beveled edge can be problematic, particularly as the bevel approaches 45º and the plane gets “tippy.” Also, it’s difficult to get a good bevel established – starting on the small corner of the stock can be awkward.

I found it’s best to bevel the two pieces at the same time; the exact angle is less important than having complementary angles. I clamp the two pieces one on top of the other and offset the pair by the thickness of the stock. This creates the perfect setup for a 45º angle.

The plane is much easier to start because it rides on two points to establish the bevel. With a good beginning, it’s easy to follow through while maintaining the angle. When the bevels all meet you know you have a completed the task.

To plane the full thickness of the wood, it’s best to raise the work off the bench (a 1⁄4” spacer will suffice). This allows the plane’s corner to ride on the benchtop and you don’t need to perform a balancing act.

If you need to bevel to a different angle, simply adjust the offset of the two workpieces and the angle can easily be changed.

Also, if you need to bevel a single piece, this technique works well with the addition of a fillister plane. Simply scribe the angle on the end of the piece, strike a rabbet with your fillister that coincides with the angle you want, then use the same technique to plane your angle. –Joshua Pierce

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.