We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When making tenons for breadboard ends and other wide workpieces, the router is my tool of choice. Ensuring perfectly aligned rabbet shoulders on both sides of the board was a problem until I started using this shopmade collar jig. I just slip it over the end of the board and clamp it in place to serve as a double-sided router fence.

When making tenons for breadboard ends and other wide workpieces, the router is my tool of choice. Ensuring perfectly aligned rabbet shoulders on both sides of the board was a problem until I started using this shopmade collar jig. I just slip it over the end of the board and clamp it in place to serve as a double-sided router fence.

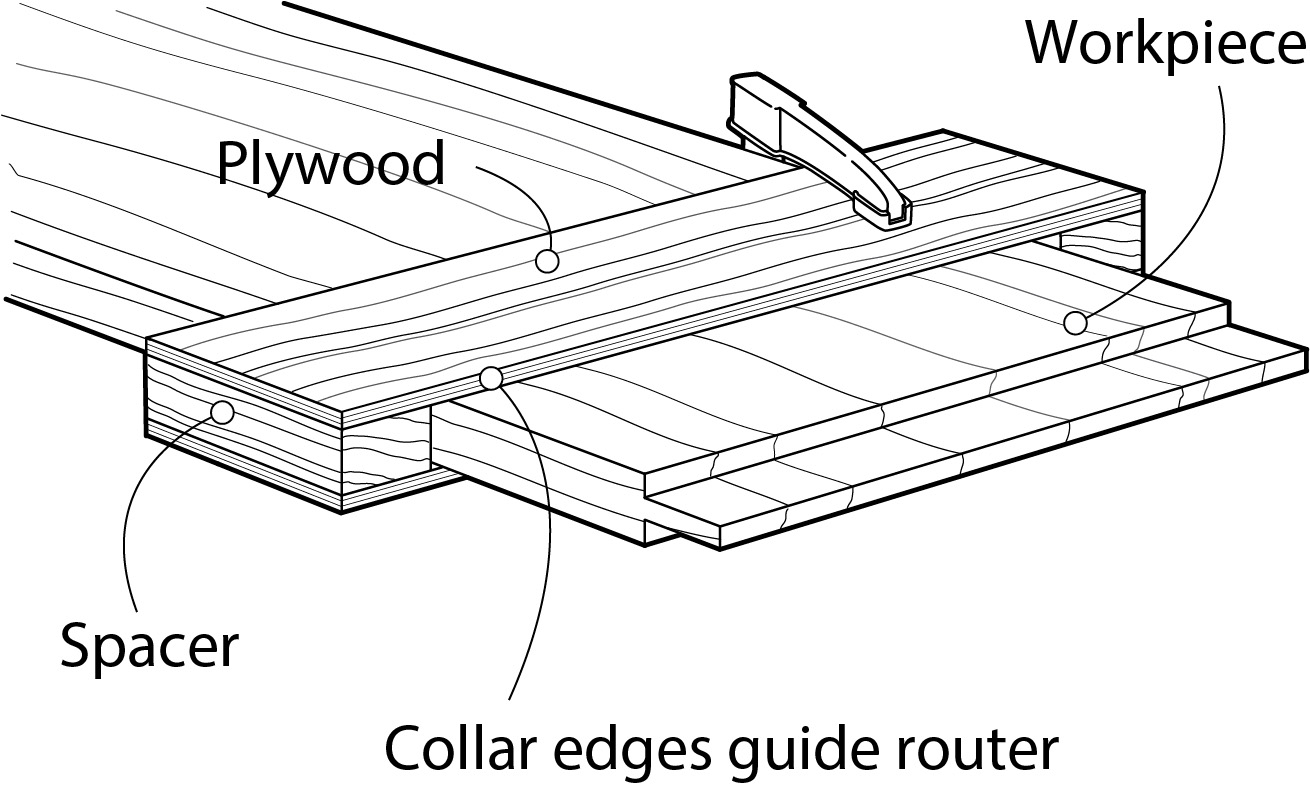

I make this jig from two strips of 1⁄4″-thick plywood about 5″ wide and a few inches longer than the width of my workpiece. I nail or screw a couple spacers between the ends of the strips, using scrap that’s just a bit thicker than my workpiece. The exact distance between the spacers is unimportant, but I keep them within an inch or so of the workpiece on each end for easy positioning. I don’t worry about perfectly aligning the plywood pieces because I run the assembly through my table saw afterward to ensure perfect alignment of the fence edges.

When setting up the jig, I locate it for the desired tenon length, then clamp the plywood to the workpiece at the end. To rout a centered tenon, I simply flip the jigged workpiece after each pass, and keep at it until the tenon reaches my desired thickness. — Steve Gross

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.