We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Establishing Depth Reference

A recent project required making a series of small wooden panels with shallow concave faces. For efficiency and accuracy, I decided to make a series of preliminary cuts on the table saw to establish the basic concave surface, then clean up the faces with an angle grinder and disc sander. It worked great.

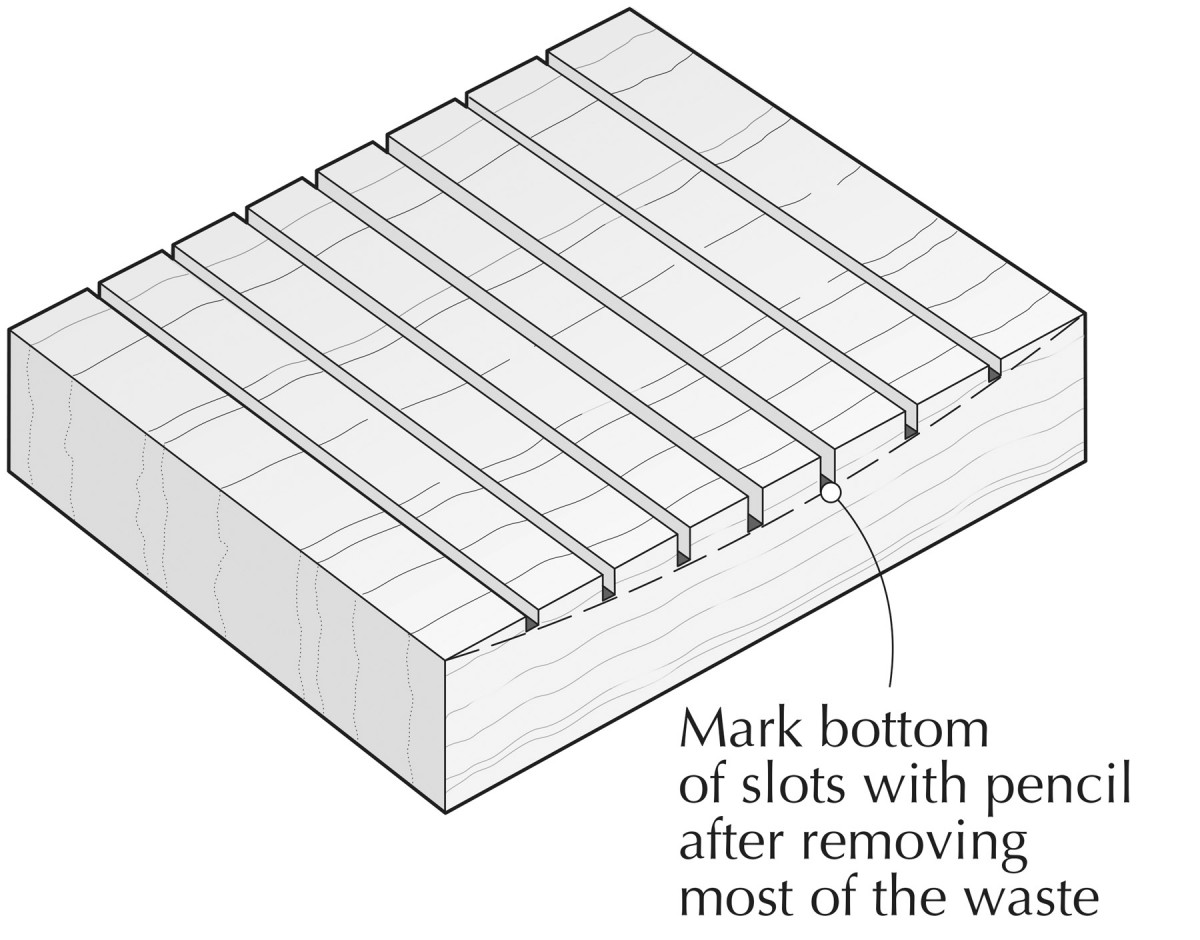

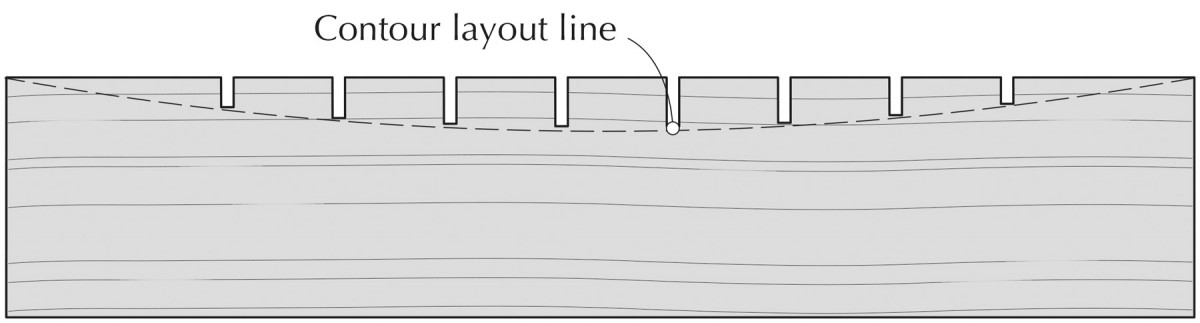

After marking the contour on the end of a workpiece, I set my table saw blade to cut just shy of the contour line for my first series of identical cuts. Then I moved my rip fence, reset the blade height and made the next series of cuts. After completing all the reference cuts, it was easy to then grind away most of the waste. When I was 1⁄8” or so from the desired surface, I stopped and drew pencil lines in the shallow remainder of the saw kerfs. This provided a very clear reference for the final rough grinding and finish sanding. As long as I stopped just after the pencil lines disappeared, I was assured of a nearly perfect shape. The same principle can be applied to a variety of shapes. And, for that matter, you can use a portable circular saw or drill for the job. — Don Pinkal

After marking the contour on the end of a workpiece, I set my table saw blade to cut just shy of the contour line for my first series of identical cuts. Then I moved my rip fence, reset the blade height and made the next series of cuts. After completing all the reference cuts, it was easy to then grind away most of the waste. When I was 1⁄8” or so from the desired surface, I stopped and drew pencil lines in the shallow remainder of the saw kerfs. This provided a very clear reference for the final rough grinding and finish sanding. As long as I stopped just after the pencil lines disappeared, I was assured of a nearly perfect shape. The same principle can be applied to a variety of shapes. And, for that matter, you can use a portable circular saw or drill for the job. — Don Pinkal

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.