We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I recently thought I’d outfit my portable “benchtop” table saw with a zero-clearance throat plate to reduce tear-out and to prevent narrow strips from falling down through the wide throat opening. Unfortunately, the throat plate opening is very shallow and requires accommodating numerous odd-shaped tabs, so making a custom throat plate wasn’t so easy. I decided to take a simpler approach.

I recently thought I’d outfit my portable “benchtop” table saw with a zero-clearance throat plate to reduce tear-out and to prevent narrow strips from falling down through the wide throat opening. Unfortunately, the throat plate opening is very shallow and requires accommodating numerous odd-shaped tabs, so making a custom throat plate wasn’t so easy. I decided to take a simpler approach.

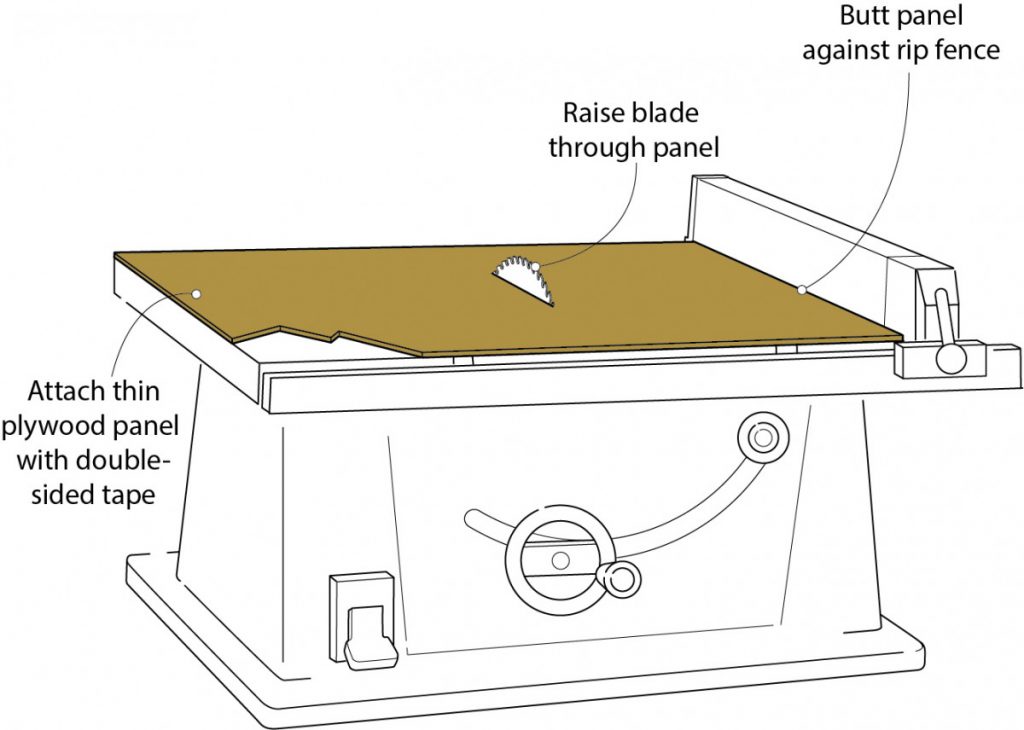

I set the rip fence for my intended rip, and measured the entire saw table area to the left of the fence. I then cut a thin plywood panel to match the area. After resetting the rip fence for my desired original cut, I attached the panel to the table with double-stick tape at the saw table edges and near the blade slot. I temporarily clamped down a board near the center of the table, then raised the blade through the panel. Voilà! I had a zero-clearance blade slot.

After making my rip cut, I stashed the panel for future use when making a similar or narrower rip cut, which simply involves shifting the panel as necessary. I keep a few of these panels in various sizes because they can be used time and again until they’re too slotted to work well. — Bruce Dorn

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.